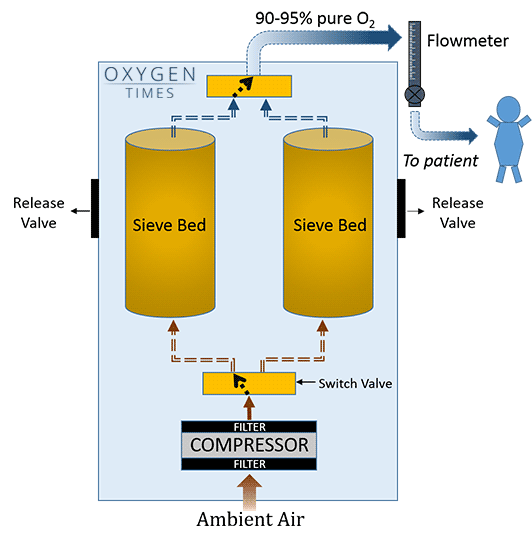

The composition of air (78% Nitrogen, 21% Oxygen and 1% other gases like Carbon Dioxide, Argon, etc.) clearly shows that air is mainly comprised of two gases: Nitrogen and Oxygen [together 99%]. If Nitrogen is removed from air, the primary gas remaining would be Oxygen with purity of about 90-95%. An Oxygen Concentrator uses this idea with the basic principle of Pressure Swing Adsorption (PSA) to deliver 90-99% pure oxygen.

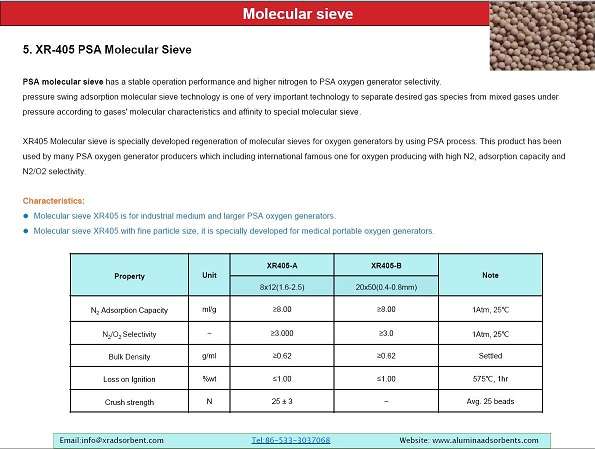

PSA oxygen concentrator include house use and hospital use. In here, we simply introduce PSA oxygen generator. The molecular sieve in PSA oxygen concentrator is 5A, 13X and XR405

- Series of filters: To filter out impurities present in air

- Air Compressor: To push room air into the machine and forward it to the molecular sieve beds.

- 2 Molecular Sieve Beds – Zeolite (Micro porous Aluminosilicate mineral): Have the ability to trap Nitrogen.

- Switch valve: Switches the output of compressor between the 2 molecular sieve beds

- Oxygen outlet: An opening that gives out oxygen to the patient

- Flow meter: To set the flow in Litres Per Minute (LPM)

Working

- Ambient air (room air) passing through a series of filters is drawn into the machine by a compressor.

- This air is compressed into the 1st molecular sieve bed and all the Nitrogen is adsorbed. The molecular sieve beds are porous & thus have large surface area due to which they adsorb large amount of Nitrogen.

- Now because air had only Nitrogen and Oxygen as main components; the primary gas that remains is Oxygen. This Oxygen has a concentration of up to 95% and is ready to be supplied to patient via Oxygen delivery system like Nasal Cannula, Oxygen mask, etc.

- The compressor keeps on compressing air into the 1st molecular sieve bed till it gets saturated (filled) by Nitrogen. The sieve bed usually gets saturated at pressure of 20 psi.

- Just before 1st molecular sieve bed gets saturated, the Switch Valve comes into action and output of the air compressor is immediately switched to 2nd sieve bed i.e. the compressor starts compressing air to the 2nd molecular sieve.

- While this sieve bed gets saturated by Nitrogen, the Nitrogen that was trapped in the 1st sieve bed is vented out. The little Nitrogen that is left in the sieve bed after discharging is removed by back-flushing of Oxygen from the other sieve bed.

- The switch valve again switches the output of air compressor back to the 1st sieve bed as soon as the 2nd sieve bed approaches saturation.

- This process keeps on repeating to ensure continuous flow of Oxygen.

- This process of switching the sieve beds is known as Pressure Swing Adsorption (PSA).

- The output of Oxygen is then controlled using a flowmeter where the flow can be set manually in Litres Per Minute (LPM).

- Oxygen flows out through an outlet where an Oxygen delivery system like nasal cannula or a mask is usually connected via humidifier.

Zibo XiangRun Environment Engineering Co., Ltd.

Zibo XiangRun Environment Engineering Co., Ltd.